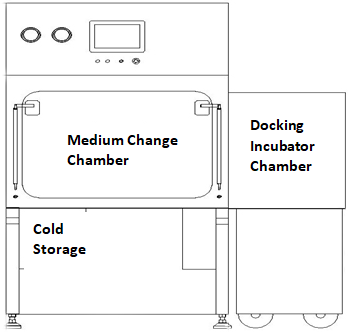

The cell therapy isolator integrates cell culture-related functional components such as centrifuges and CO2 incubators to complete cell culture-related operations in a closed aseptic environment to meet the GMP production requirements of cell products.

Vertical laminar flow;

Built-in Vaporized Hydrogen Peroxide (VHPS) Generator for thorough decontamination;

Adopts dry VHPS technology to avoid condensation;

Unique concentration dynamiclly control technology to avoid the VHPS concentration is too high or too low;

Pressure control technology to minimize the risk of VHPS penerating in the package;

Temperature control during the decontamination process to minimize the high temperature affecting the cell viability;

The chamber cleanliness is monitored by the air sampler and particle counter;

Movable cell incubator can avoid the cross contamination;

Automatic medium replacement modular can improve the efficiency and low the labor cost;

Modular design which is easily installed in class D background ;

Validation service: DQ,IQ,OQ,PQ,VHPS penetration test.

Cleanliness Class: ISO5 ClassA

HEPA Filters:H14, HEPA≥99.995%,@0.3um

Bio-decontamination time: approx. 2.5 hours,reach 6-log SAL

illumination: >500lux

Power Supply: 380V 50Hz

Pressure: 20~80Pa adjustable

Overall Dimensions (LxWxH):5500mm×1205mm×2600mm(Could be customoized)

Structure: SUS 316L and 15mm tempered glass

Incubator temperature: 37℃±0.2

Temperature resolution: 0.1℃

Temperature fluctuation: ±0.2℃

CO2 concentration: 5%

Cold storage temperature: 2-8℃

Rewarming temperature: 37℃

Medium replacement speed: 5min/dish

Noise≤65dB(A)

Designed for the users who require sterile conditions for R&D or pilot production of cell & gene products.

Technical specifications are subject to change without notice. Copyright reserved by Tailin.

CN

CN